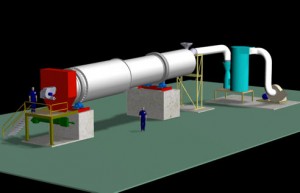

Calciners: SC dryer-calciner

Converts mussel shells into calcium carbonate

For drying and calcinating the residue from the mussel canning industry. It converts mussel shells into calcium carbonate of 96% purity, which can then be used in the chemical industry, as fertilizer or in construction. It can also be used to make any organic residue inert.

This machine features a continuous and controlled process whose temperature does not exceed the calcination temperature of 600ºC, and the heat used is reused in the first drying stage.

The process is controlled using SCADA software, allowing the flows of gases and the temperature to be monitored at five key points including inside the revolving drum, as well as the speed, power and consumption.

This machine, which is unique in the world, can process 20 tonnes of mussel shells per hour. It can run on fuel oil, natural gas or cogeneration gases. Power consumption is low: just 3000 therms/hour. Smaller versions are available down to 500kg per hour.